MENUMENU

About Us

Scag Power Equipment

Since 1983, Scag Power Equipment has manufactured “Simply the Best” commercial and residential lawn mowers, debris/turf management and compact construction equipment money can buy. Scag’s innovation and attention to quality is known and respected throughout the industry. If you are looking for the highest-quality, best-built, best-performing lawn mower, debris/turf management or compact construction equipment — proudly designed, fabricated and assembled in the USA — look no further.

About Scag Power Equipment

Scag Power Equipment, a division of Metalcraft of Mayville, Inc., was founded in 1983. Originally, the Scag® product was manufactured under contract with Metalcraft of Mayville in Mayville, Wisconsin. In 1986, Metalcraft purchased Scag Power Equipment, marking the beginning of a tremendous period of growth for the company.

From just one commercial lawn mower model, a gear-drive rider, to over 60 commercial and residential lawn mower models today, Scag Power Equipment has become one of the largest independent manufacturers of commercial & residential mowing, debris/turf management and compact construction equipment in the world. Scag Power Equipment’s innovation and attention to quality is known and respected throughout the power equipment industry. Mowers and accessories are designed to be user-friendly, with an emphasis on quality, performance, ease of maintenance, profitability and long life.

Why Buy A Scag

Independent, American Spirit

Being independently-owned means our design decisions are not compromised by a large corporate office that also sells sprinklers, vacuum cleaners or other “widgets.” We are not forced to manufacture products that are just “good enough.” The entire Scag Team focuses all of its resources on designing, manufacturing and assembling the finest outdoor power equipment money can buy. We are hardworking Americans making “Simply the Best” equipment that our customers can depend on.

Every machine starts off as sheet steel or tube steel. We punch, press, bend, cut, weld, paint, assemble, package and ship our mowers, and we do it all in our Wisconsin factories (Mayville, West Bend, Beaver Dam, Fall River, and New Berlin). We even mold our own plastic tanks in our dedicated plastics facility in Horicon, WI. Scag makes its own outdoor power equipment; nobody else makes machines for us… and we do not make mowers for other brands.

+ Read More

×

Independent, American Spirit

Being independently-owned means our design decisions are not compromised by a large corporate office that also sells sprinklers, vacuum cleaners or other “widgets.” We are not forced to manufacture products that are just “good enough.” The entire Scag Team focuses all of its resources on designing, manufacturing and assembling the finest outdoor power equipment money can buy. We are hardworking Americans making “Simply the Best” equipment that our customers can depend on.

Every machine starts off as sheet steel or tube steel. We punch, press, bend, cut, weld, paint, assemble, package and ship our mowers, and we do it all in our Wisconsin factories (Mayville, West Bend, Beaver Dam, Fall River, and New Berlin). We even mold our own plastic tanks in our dedicated plastics facility in Horicon, WI. Scag makes its own outdoor power equipment; nobody else makes machines for us… and we do not make mowers for other brands.

Experience

Since 1983, Scag Power Equipment has been producing heavy-duty, commercial and residential mowers, debris/turf management and compact construction equipment. This gives us the experience needed to know what really works, and what doesn’t. We also have the experience to know that we don’t know everything… We listen to our customers and constantly make the changes needed to meet their needs. In fact, every Scag mower receives many improvements and enhancements on a constant basis. Even the smallest improvements are important in creating the “Simply the Best” machines on the market. This constant product evolution has enabled us to retain our reputation as the premiere outdoor power equipment line in the industry. You can find machines that cost less; however, you get what you pay for.

+ Read More

×

Experience

Since 1983, Scag Power Equipment has been producing heavy-duty, commercial and residential mowers, debris/turf management and compact construction equipment. This gives us the experience needed to know what really works, and what doesn’t. We also have the experience to know that we don’t know everything… We listen to our customers and constantly make the changes needed to meet their needs. In fact, every Scag mower receives many improvements and enhancements on a constant basis. Even the smallest improvements are important in creating the “Simply the Best” machines on the market. This constant product evolution has enabled us to retain our reputation as the premiere outdoor power equipment line in the industry. You can find machines that cost less; however, you get what you pay for.

Design and Testing

We employ an elite group of research and development specialists, designers and engineers dedicated to producing lawn mowers that cut faster, cut better, last longer and ultimately make you more profitable. Computer-aided design (CAD) and Pro-E, combined with computer numerical control (CNC) and hands-on fabrication are utilized in the initial creation of every product. Every Scag model is operated extensively in specialized laboratories that utilize sophisticated, computerized testing equipment. The laboratory testing process is handled by a dedicated Test Engineering Team. This initial testing stage allows us to closely monitor mower and individual-component performance to quickly identify any potential improvements that can be made. We also use test facilities in various locations across North America in various climates and grass types.

+ Read More

×

Design and Testing

We employ an elite group of research and development specialists, designers and engineers dedicated to producing lawn mowers that cut faster, cut better, last longer and ultimately make you more profitable. Computer-aided design (CAD) and Pro-E, combined with computer numerical control (CNC) and hands-on fabrication are utilized in the initial creation of every product. Every Scag model is operated extensively in specialized laboratories that utilize sophisticated, computerized testing equipment. The laboratory testing process is handled by a dedicated Test Engineering Team. This initial testing stage allows us to closely monitor mower and individual-component performance to quickly identify any potential improvements that can be made. We also use test facilities in various locations across North America in various climates and grass types.

Quality and Construction

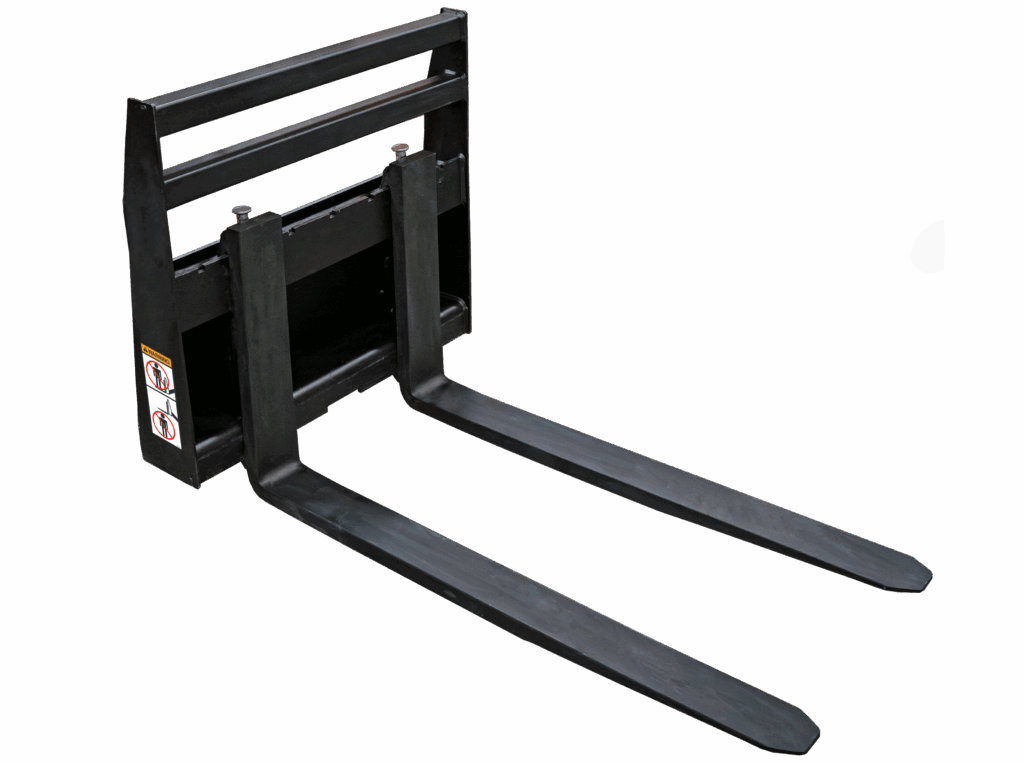

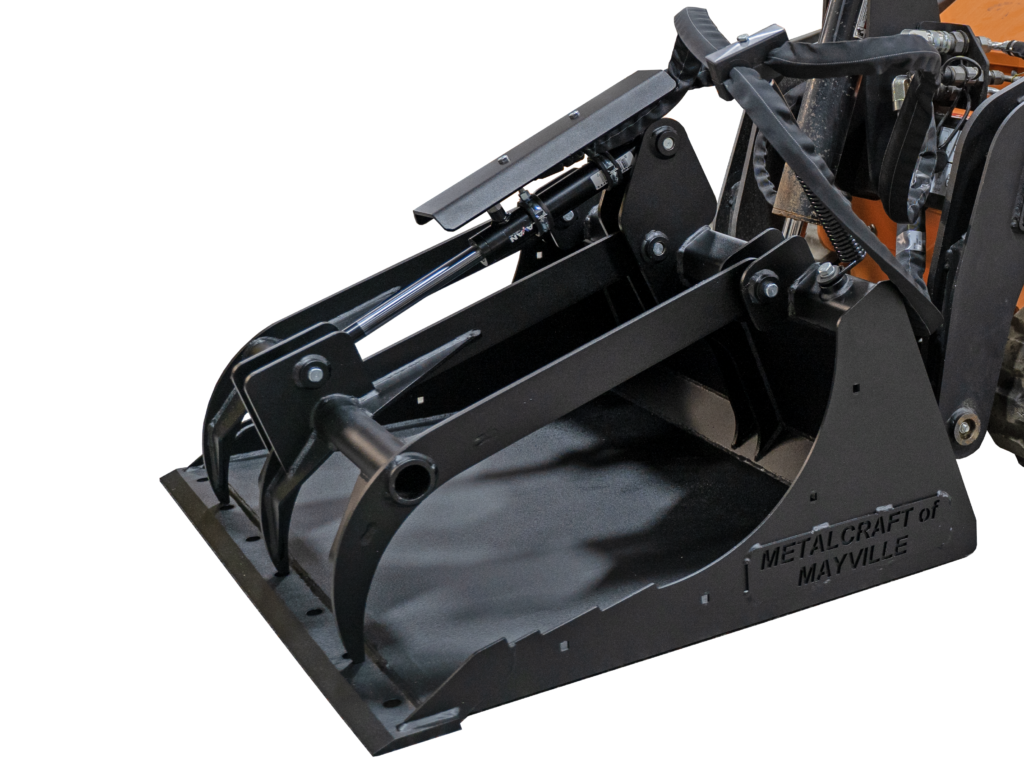

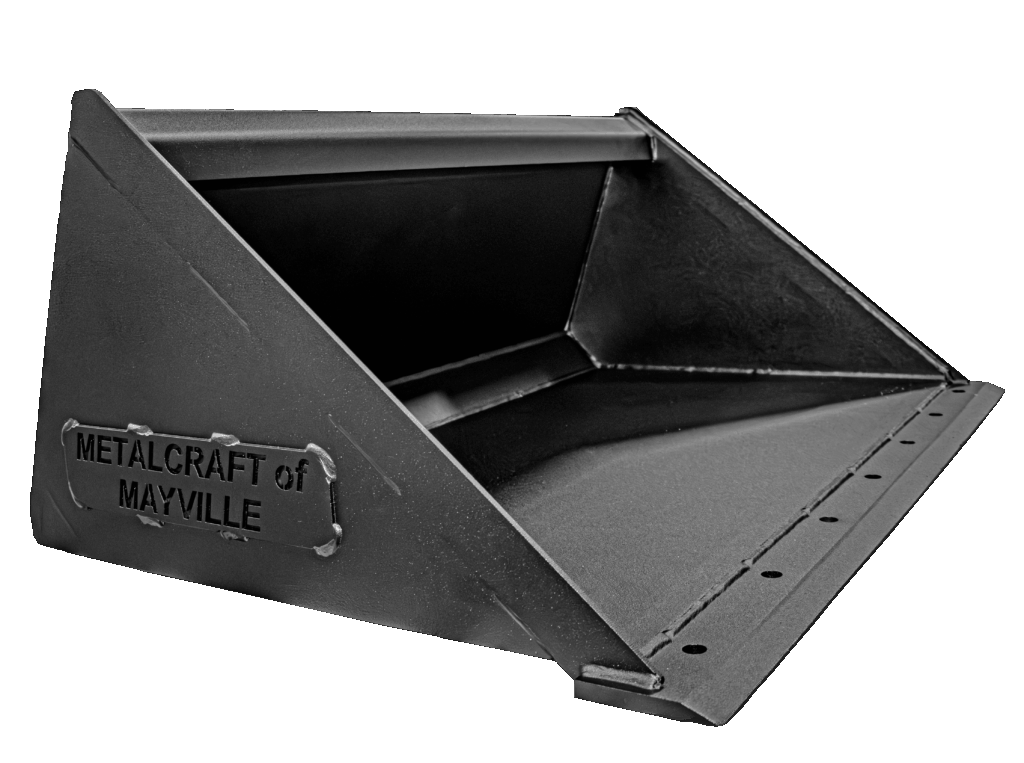

Scag products are fabricated at our parent company, Metalcraft of Mayville, Inc., one of the largest independently owned manufacturers of commercial and residential power equipment in North America. Metalcraft also manufactures thousands of various components for a number of Fortune 500 companies in the construction, forestry, agriculture and material-handling industries, as well as for the U.S. Military.

Scag Power Equipment is one of the last commercial power-equipment companies that actually manufactures their own components. Other mower “manufacturers” are simply assemblers, bolting together parts that other companies have made for them. In fact, virtually every “Scag Cat’s Eye Gold” and textured black fabricated steel component on our mowers is manufactured from scratch by Scag (except for wheels). Sheet metal and tube steel comes in one end of the factory, and the world’s best outdoor power equipment goes out the other end. Additionally, all of our plastic fuel tanks are also made by our own Metalcraft Plastics Group. Manufacturing our own component parts allows us greater flexibility in design and more control over the quality of the parts we use in our mowers. Ultimately, we control our own destiny and are able to react quickly with new designs and product enhancements.

Scag mowers are crafted and assembled by highly-trained individuals using the latest technologies, in conjunction with cutting-edge solutions from our Metalcraft Automation Group. Each mower is run at the end of the assembly line to ensure that the following items are up to specification: engine RPM is set, all safety switches are checked for proper operation, fluids are filled, systems are checked for leaks, and neutral and tracking adjustments are set using special dynamometers that apply load to the drive system. These steps add to the value of every Scag mower and ensure the product is the best it can be when it leaves our factory.

Details, details, details. We encourage you to take the time to really examine our mowers and compare them to the “competition.” Pay special attention to the details like ease of service, wiring harness looms and routing, weld quality, component fit and construction, and the operator’s platform. There are lots of lawn mower makers, but only one is the best. We encourage you to see for yourself that Scag is the best by taking the time to really examine the details. It will not take long to find the many differences that place Scag in front of the pack.

+ Read More

×

Quality and Construction

Scag products are fabricated at our parent company, Metalcraft of Mayville, Inc., one of the largest independently owned manufacturers of commercial and residential power equipment in North America. Metalcraft also manufactures thousands of various components for a number of Fortune 500 companies in the construction, forestry, agriculture and material-handling industries, as well as for the U.S. Military.

Scag Power Equipment is one of the last commercial power-equipment companies that actually manufactures their own components. Other mower “manufacturers” are simply assemblers, bolting together parts that other companies have made for them. In fact, virtually every “Scag Cat’s Eye Gold” and textured black fabricated steel component on our mowers is manufactured from scratch by Scag (except for wheels). Sheet metal and tube steel comes in one end of the factory, and the world’s best outdoor power equipment goes out the other end. Additionally, all of our plastic fuel tanks are also made by our own Metalcraft Plastics Group. Manufacturing our own component parts allows us greater flexibility in design and more control over the quality of the parts we use in our mowers. Ultimately, we control our own destiny and are able to react quickly with new designs and product enhancements.

Scag mowers are crafted and assembled by highly-trained individuals using the latest technologies, in conjunction with cutting-edge solutions from our Metalcraft Automation Group. Each mower is run at the end of the assembly line to ensure that the following items are up to specification: engine RPM is set, all safety switches are checked for proper operation, fluids are filled, systems are checked for leaks, and neutral and tracking adjustments are set using special dynamometers that apply load to the drive system. These steps add to the value of every Scag mower and ensure the product is the best it can be when it leaves our factory.

Details, details, details. We encourage you to take the time to really examine our mowers and compare them to the “competition.” Pay special attention to the details like ease of service, wiring harness looms and routing, weld quality, component fit and construction, and the operator’s platform. There are lots of lawn mower makers, but only one is the best. We encourage you to see for yourself that Scag is the best by taking the time to really examine the details. It will not take long to find the many differences that place Scag in front of the pack.

Performance and Productivity

Whether on the job or at home, we know that your time is valuable. Commercial cutters can’t afford anything less than the most productive machine possible. Homeowners have more important things to move on to after tending to their yards. Each and every Scag machine is built for maximum performance and productivity to help you get the job done quickly and reliably.

Proven, high-performance engines and drive systems keep you rolling, even in the toughest conditions. Each new engine, hydraulic pump, wheel motor or transaxle must establish a strong track record of performance and dependability before it can earn a place on a Scag machine.

Industry-envied Velocity Plus, Advantage and Hero cutter decks provide a quality-of-cut above anything you’ve previously experienced. Scag’s legendary, heavy-duty cutter deck spindles ensure flawless performance, year after year.

+ Read More

×

Performance and Productivity

Whether on the job or at home, we know that your time is valuable. Commercial cutters can’t afford anything less than the most productive machine possible. Homeowners have more important things to move on to after tending to their yards. Each and every Scag machine is built for maximum performance and productivity to help you get the job done quickly and reliably.

Proven, high-performance engines and drive systems keep you rolling, even in the toughest conditions. Each new engine, hydraulic pump, wheel motor or transaxle must establish a strong track record of performance and dependability before it can earn a place on a Scag machine.

Industry-envied Velocity Plus, Advantage and Hero cutter decks provide a quality-of-cut above anything you’ve previously experienced. Scag’s legendary, heavy-duty cutter deck spindles ensure flawless performance, year after year.

Product Support

We understand the importance of “no downtime” and what it means to your business. Because of this, we sell our products through a worldwide distributor and dealer network. Every distributor of Scag equipment has their own parts department, technical service department and sales department to better serve the Scag dealer and ultimately you, the Scag customer. Using distribution ensures local parts availability and it gives the Scag dealer a local source for technical service, parts and sales support.

The Scag Factory Technical Service Department is in constant communication with our field representatives, regional and distribution managers, dealers and customers. Rest assured that in the unlikely event of any trouble, the entire Scag family will be there to help. Click here for a list of Scag dealers in your area.

+ Read More

×

Product Support

We understand the importance of “no downtime” and what it means to your business. Because of this, we sell our products through a worldwide distributor and dealer network. Every distributor of Scag equipment has their own parts department, technical service department and sales department to better serve the Scag dealer and ultimately you, the Scag customer. Using distribution ensures local parts availability and it gives the Scag dealer a local source for technical service, parts and sales support.

The Scag Factory Technical Service Department is in constant communication with our field representatives, regional and distribution managers, dealers and customers. Rest assured that in the unlikely event of any trouble, the entire Scag family will be there to help. Click here for a list of Scag dealers in your area.

What It Means to Be "Simply the Best"

Eellentesque elementum, diam quis maximus feugiat, velit ante aliquam mauris, et fringilla libero ex vitae lorem. Nulla tellus purus, volutpat id felis non, facilisis malesuada sapien. Nunc nulla metus, aliquet id nisi eget, tempor laoreet odio.

Nullam semper blandit tortor vitae sodales. Aliquam nec auctor erat. Mauris ornare lacinia sodales. Curabitur elementum porta odio. Morbi eget risus vel tellus volutpat semper. Donec pharetra lobortis dui, a rhoncus erat interdum sit amet. Donec ultrices turpis vel purus lobortis, quis auctor sem consequat.

SCAG PARTNERSHIPS

Gary Sinise Foundation

Scag is proud to be a Bronze Level Sponsor of the Gary Sinise Foundation, with our charitable contribution being directed towards their First Responder Outreach program. Through this program, the Gary Sinise Foundation provides critical funding for emergency relief, training and essential equipment ensuring these heroes are able to perform to the best of their abilities.

A Soldier's Child Foundation

Scag Power Equipment proudly supports A Soldier’s Child Foundation, whose mission is to serve the children of military personnel who have lost their lives on active duty, while defending the United States of America. ASC has three points of service for the children of our fallen: birthday celebrations, mentorship programs & camps and college scholarships.

Road America

Scag is the Official Mower of Road America, one of the nation’s largest and most respected outdoor race facilities. With a facility over 600 acres large, the crew at Road America have their hands full maintaining the grounds. Scag mowers are the perfect tool for a project of this scale. Thanks to our friends at RA for being loyal Scag customers.

Our History

Scag Power Equipment Is Established

A new benchmark in commercial-grade power equipment was created.

1985

Metalcraft of Mayville Purchased Scag Power Equipment

Scag becomes a division of Metalcraft of Mayville, the contract metal manufacturer that has been making Scag mowers from its inception in 1983.

1986

Scag Introduces the Industry's First Dual-Pump, Dual-Motor Hydro Walk-Behind

Delivering up to 30% more productivity than a belt-driven walk-behind, the SWZ zero-turn mower design revolutionized the commercial mowing industry.

1990

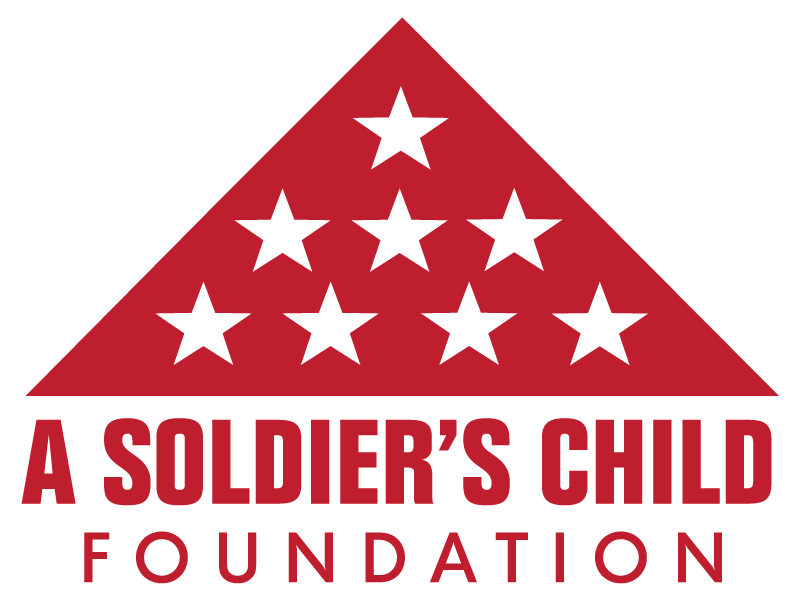

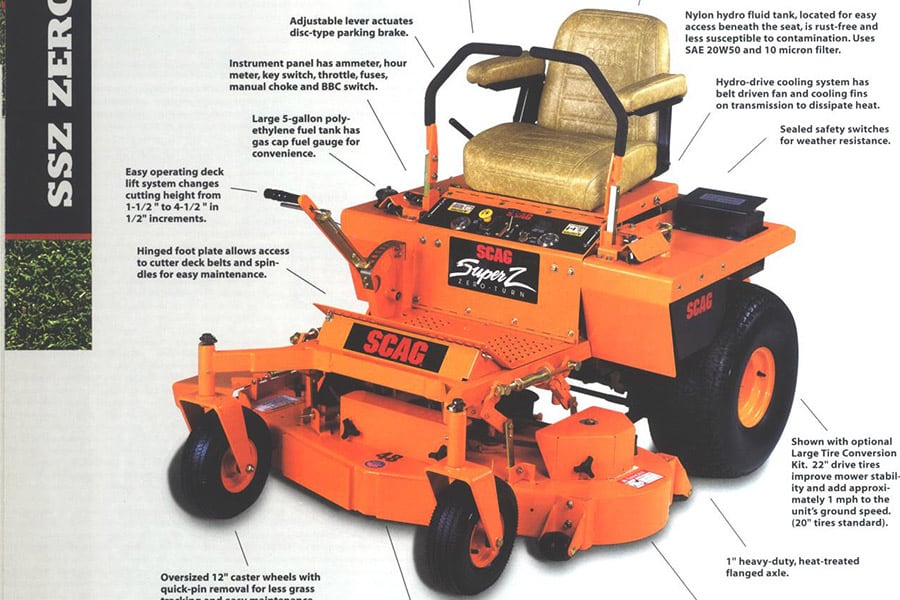

Scag Introduces the SSZ Zero-Turn Riding Mower

The Scag Super Z (SSZ) offered better handling, maneuverability and balance over the STZ, moving the zero-turn mower line forward.

1996

The Scag Turf Tiger Is Born

Still the industry benchmark, the unmatched Turf Tiger continues to mow down the "competition."

1998

The Scag Tiger Cub Is Born

This amazing zero-turn rider packed full-size performance into a compact package. The model is still in production today under the Tiger Cat® name.

2001

Turf Tiger Redesign

The Scag Turf Tiger™, Tiger Cub and Sabre Tooth were redesigned for a lower center of gravity and many other enhancements to evolve the product line.

2004

The Scag Z-Cat Is Born

The Z-Cat was an ultra-compact, commercial-grade, zero-turn riding mower.

2007

The Scag V-Ride Is Born

The V-Ride™ is a highly productive stand-on mower and is still in production today.

2010

The Scag Cheetah Is Born

With a coil-over suspension system for the operator and speeds up to 16 mph, Scag once again shows the industry that they are the leader.

2012

The Liberty Z Is Born

This was the first Scag mower designed and built exclusively for the quality-minded homeowner.

2016

The Scag Patriot Is Born

Delivering commercial-grade results at an incredible value, the Patriot is designed to exceed your expectations.

2016

The Turf Tiger II Is Born

This industry benchmark has been re-engineered to be as easy on the operator as it is efficient on tough jobs in the field.

2017

A New Look for Select Scag Models

The Scag Patriot™, Freedom Z® and Liberty® Z get a facelift as Scag adds some eye-catching showroom appeal to the lineup.

2019

THE SCAG TURF STORM IS BORN

Production of the Scag Turf Storm™, the Company’s first spreader/sprayer product, begins in the Beaver Dam facility.

2021

2023

THE SCAG AERSTORM IS BORN

The AerStorm™ stand-on aerator is introduced, Scag’s newest product category offering.

2023

THE SCAG V-RIDE XL IS BORN

Scag expands their stand-on mower offerings in a BIG and BOLD way, introducing the V-Ride XL.

2023

SCAG RACING, LLC

In early 2024, Scag Racing, LLC formed the first factory team in NHRA, which included drivers Justin Ashley (Top Fuel Dragster), Daniel Wilkerson (Funny Car) and Dave Richards (Funny Car). Scag also continued its sponsorship of Elite Motorsports drivers Erica Enders and Jeg Coughlin, Jr.

2024

Scag Makes New Tracks in the Mini Skid Steer Market

Scag breaks new ground with the Jackal, a stand-on mini skid steer that gives our customers an opportunity to achieve new levels of productivity.

2024

A favorite gets an upgrade

Scag upgrades its SFC-30 to the SFCII-30. This incredible 30” walk-behind mower is next-level in maneuverability and longevity.

1983

Scag Enhanced Gear-Driven Three-Wheel Riding Mowers

Making the three-wheel riding mowers more productive and comfortable.

1986

Belt-Driven Walk-Behind Mower Introduced

Scag releases the SW belt-drive walk-behind, providing the commercial landscaper a more compact mower for tight spaces.

1989

Scag Introduces the STZ Zero-Turn Riding Mower

This was the first zero-turn riding mower Scag released and offered tremendous productivity increases.

1992

Scag Introduces the Magnum III Three-Wheeled Riding Mower

Scag Introduces the Magnum III Three-Wheeled Riding Mower

1997

Scag Released the Cougar Bagging Mower and the Sabre Tooth Tiger

The Cougar compact bagging mower and the Sabre Tooth Tiger mower were both released in 1998.

2000

250,000th Scag Mower Built

The quarter-millionth Scag mower was tricked out with chrome wheels and a custom seat, and was donated to charity.

2002

The Scag Wildcat Is Born

The Wildcat was yet another zero-turn rider with a compact stance and the ability to provide big productivity.

2005

The Scag Freedom Z Is Born

An entry-level commercial and large property mower, the Freedom Z offers Scag quality and performance at a lower price. The Freedom Z is still in production today.

2010

Scag Introduces Propane-Powered Mowers

Scag introduces its first propane powered mower, a Scag Turf Tiger. This allows operators to mow in areas affected by air quality laws such as Ozone Action Days.

2010

Acquired Giant-Vac Line of Leaf- and Debris-Management Products

Scag purchased Giant-Vac and revamped the entire product line to create Scag Giant-Vac, high-performance leaf- and debris-handling equipment manufactured at the ultra-high level of quality that Scag customers expect.

2015

Scag Introduces the Tiger Eye Advanced Monitoring System

The Tiger Eye™ Advanced Monitoring System keeps a constant, real-time "eye" on important system functions on select Scag models.

2016

The Tiger Cat II Is Born

Re-engineered from the ground up, the all-new Tiger Cat® II has set a new benchmark for mid-sized zero-turn riders.

2016

The Scag V-Ride II Is Born

The new V-Ride™ II's exceptional results—even greater stability and unmatched comfort—leave no doubt: It's a whole new ballgame.

2019

2020

THE SCAG SFC-30 IS BORN

Production of the highly-awaited SFC-30 occurs. This 30” walk-behind mower is Scag’s smallest, and perhaps most anticipated, mower to-date.

2022

SCAG EXPANDS NHRA PARTNERSHIP

After a successful inaugural 2022 season in NHRA, Scag expands its involvement in the sport and becomes the Official Power Equipment Provider of NHRA.

2023

THE SCAG SFC-21 IS BORN

The SFC-21 walk-behind mower, Scag’s second finish-cut mower, is now available, allowing customers to fill their trailers and garages with a more “Cat’s Eye Gold” products.

2023

PRESTIGIOUS RECOGNITION

For the sixth time, Scag earns the prestigious Equipment Dealers Association (EDA) “Dealer’s Choice Award.”

2024

A SECOND TURF STORM IS BORN

Scag introduces a second Turf Storm into the spreader/sprayers product line, rebranding the original Turf Storm as Turf Storm XL.

2024

A zero-turn machine for the homeowner

Scag introduces the SLS so everyone can come home to a professional-grade quality-of-cut.

2024

Scag Power Equipment Is Established

A new benchmark in commercial-grade power equipment was created.

Scag Enhanced Gear-Driven Three-Wheel Riding Mowers

Making the three-wheel riding mowers more productive and comfortable.

Metalcraft of Mayville Purchased Scag Power Equipment

Scag becomes a division of Metalcraft of Mayville, the contract metal manufacturer that has been making Scag mowers from its inception in 1983.

Belt-Driven Walk-Behind Mower Introduced

Scag releases the SW belt-drive walk-behind, providing the commercial landscaper a more compact mower for tight spaces.

Scag Introduces the Industry's First Dual-Pump, Dual-Motor Hydro Walk-Behind

Delivering up to 30% more productivity than a belt-driven walk-behind, the SWZ zero-turn mower design revolutionized the commercial mowing industry.

Scag Introduces the STZ Zero-Turn Riding Mower

This was the first zero-turn riding mower Scag released and offered tremendous productivity increases.

Scag Introduces the SSZ Zero-Turn Riding Mower

The Scag Super Z (SSZ) offered better handling, maneuverability and balance over the STZ, moving the zero-turn mower line forward.

Scag Introduces the Magnum III Three-Wheeled Riding Mower

Scag Introduces the Magnum III Three-Wheeled Riding Mower

The Scag Turf Tiger Is Born

Still the industry benchmark, the unmatched Turf Tiger continues to mow down the "competition."

Scag Released the Cougar Bagging Mower and the Sabre Tooth Tiger

The Cougar compact bagging mower and the Sabre Tooth Tiger mower were both released in 1998.

The Scag Tiger Cub Is Born

This amazing zero-turn rider packed full-size performance into a compact package. The model is still in production today under the Tiger Cat® name.

250,000th Scag Mower Built

The quarter-millionth Scag mower was tricked out with chrome wheels and a custom seat, and was donated to charity.

Turf Tiger Redesign

The Scag Turf Tiger™, Tiger Cub and Sabre Tooth were redesigned for a lower center of gravity and many other enhancements to evolve the product line.

The Scag Wildcat Is Born

The Wildcat was yet another zero-turn rider with a compact stance and the ability to provide big productivity.

The Scag Z-Cat Is Born

The Z-Cat was an ultra-compact, commercial-grade, zero-turn riding mower.

The Scag Freedom Z Is Born

An entry-level commercial and large property mower, the Freedom Z offers Scag quality and performance at a lower price. The Freedom Z is still in production today.

The Scag V-Ride Is Born

The V-Ride™ is a highly productive stand-on mower and is still in production today.

Scag Introduces Propane-Powered Mowers

Scag introduces its first propane powered mower, a Scag Turf Tiger. This allows operators to mow in areas affected by air quality laws such as Ozone Action Days.

The Scag Cheetah Is Born

With a coil-over suspension system for the operator and speeds up to 16 mph, Scag once again shows the industry that they are the leader.

Acquired Giant-Vac Line of Leaf- and Debris-Management Products

Scag purchased Giant-Vac and revamped the entire product line to create Scag Giant-Vac, high-performance leaf- and debris-handling equipment manufactured at the ultra-high level of quality that Scag customers expect.

The Liberty Z Is Born

This was the first Scag mower designed and built exclusively for the quality-minded homeowner.

Scag Introduces the Tiger Eye Advanced Monitoring System

The Tiger Eye™ Advanced Monitoring System keeps a constant, real-time "eye" on important system functions on select Scag models.

The Scag Patriot Is Born

Delivering commercial-grade results at an incredible value, the Patriot is designed to exceed your expectations.

The Tiger Cat II Is Born

Re-engineered from the ground up, the all-new Tiger Cat® II has set a new benchmark for mid-sized zero-turn riders.

The Turf Tiger II Is Born

This industry benchmark has been re-engineered to be as easy on the operator as it is efficient on tough jobs in the field.

The Scag V-Ride II Is Born

The new V-Ride™ II's exceptional results—even greater stability and unmatched comfort—leave no doubt: It's a whole new ballgame.

A New Look for Select Scag Models

The Scag Patriot™, Freedom Z® and Liberty® Z get a facelift as Scag adds some eye-catching showroom appeal to the lineup.

THE SCAG TURF STORM IS BORN

Production of the Scag Turf Storm™, the Company’s first spreader/sprayer product, begins in the Beaver Dam facility.

THE SCAG SFC-30 IS BORN

Production of the highly-awaited SFC-30 occurs. This 30” walk-behind mower is Scag’s smallest, and perhaps most anticipated, mower to-date.

SCAG EXPANDS NHRA PARTNERSHIP

After a successful inaugural 2022 season in NHRA, Scag expands its involvement in the sport and becomes the Official Power Equipment Provider of NHRA.

THE SCAG AERSTORM IS BORN

The AerStorm™ stand-on aerator is introduced, Scag’s newest product category offering.

THE SCAG SFC-21 IS BORN

The SFC-21 walk-behind mower, Scag’s second finish-cut mower, is now available, allowing customers to fill their trailers and garages with a more “Cat’s Eye Gold” products.

THE SCAG V-RIDE XL IS BORN

Scag expands their stand-on mower offerings in a BIG and BOLD way, introducing the V-Ride XL.

PRESTIGIOUS RECOGNITION

For the fifth time, and fourth consecutive year, Scag earns the prestigious Equipment Dealers Association (EDA) “Dealer’s Choice Award.”

SCAG RACING, LLC

In early 2024, Scag Racing, LLC formed the first factory team in NHRA, which included drivers Justin Ashley (Top Fuel Dragster), Daniel Wilkerson (Funny Car) and Dave Richards (Funny Car). Scag also continued its sponsorship of Elite Motorsports drivers Erica Enders and Jeg Coughlin, Jr.

A SECOND TURF STORM IS BORN

Scag introduces a second Turf Storm into the spreader/sprayers product line, rebranding the original Turf Storm as Turf Storm XL.

Scag Makes New Tracks in the Mini Skid Steer Market

Scag breaks new ground with the Jackal, a stand-on mini skid steer that gives our customers an opportunity to achieve new levels of productivity.

A zero-turn machine for the homeowner

Scag introduces the SLS so everyone can come home to a professional-grade quality-of-cut.

A favorite gets an upgrade

Scag upgrades its SFC-30 to the SFCII-30. This incredible 30” walk-behind mower is next-level in maneuverability and longevity.

1983

1985

1986

1986

1989

1990

1992

1996

1997

1998

2000

2001

2002

2004

2005

2007

2010

2010

2010

2012

2015

2016

2016

2016

2016

2017

2019

2019

2020

2021

2022

2022

2023

2023

2023

2023

2024

2024

2024

2024

2024

Find a Dealer

Scag Power Equipment is represented across the globe by a network of authorized dealers. Scag dealers are your best source for obtaining timely sales assistance, reliable technical service, as well as Genuine Scag Parts.