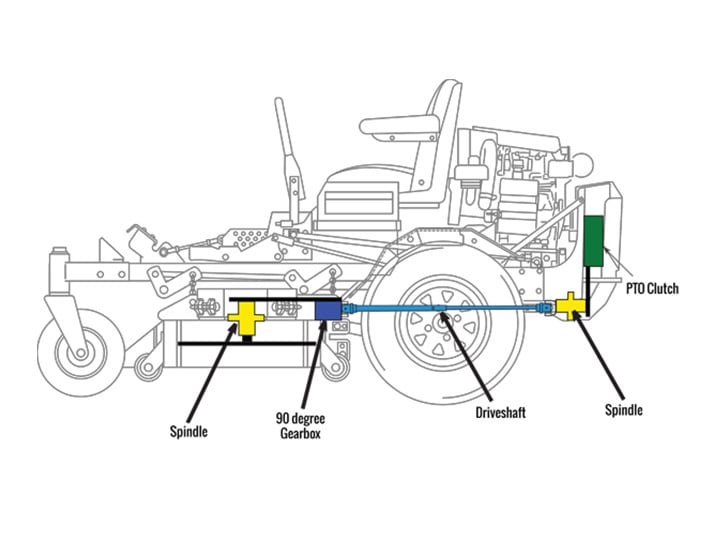

High-performance, high-horsepower machines require high-strength drive components and drive systems to ensure reliability and productivity. Scag® understands this requirement and it is apparent in the design of every mower we build. Here’s an overview of how we transmit solid, no-slip, reliable power to our cutter decks on all Turf Tiger™ models.

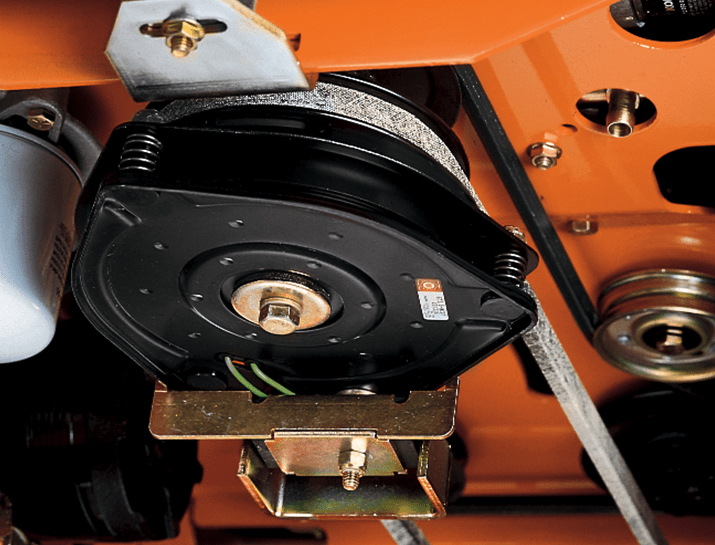

- The engine powers a heavy-duty Ogura electric clutch.

- The Ogura clutch turns a Scag-tough drive spindle via a self-adjusting, Kevlar® corded belt.

- The drive spindle is directly attached to a double-clamped driveshaft that runs to the cutter deck.

- The driveshaft is attached to a simple, 90-degree gearbox that transmits power to the Kevlar-corded, self-adjusting spindle drive belt.

- The self-adjusting spindle drive belt turns the blade spindles that are attached to the cutter blades.